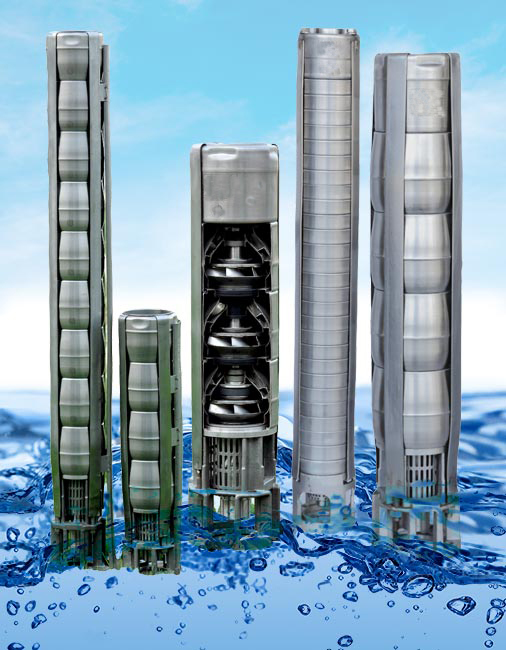

Borana 6-inch Stainless Steel Submersible Pumps (50/60 Hz)

Borana Submersible pumps are designed to be highly durable and long lasting. In the comparison of other above ground water pumps, Borana’s Submersible pump causes fewer mechanical problem, avoids pump cavitations and other problems occurred due to high elevation between pump and water surface. They are efficiently designed for the wide applications like irrigation system in agriculture, drainage, sewage, boosting, underground lowering, and water supply in domestic or residential areas as well as in various industrial applications.

Technical Specifications

Power Range kW/HP: 0.75hp (0.55kw) to 75hp (55kw)

Rated Speed: 2880 RPM

Head Range: up to 565 meters (1854 feet)

Discharge Range: 1300 LPM to 33.3 LPM

Flow Range: up to 78 m³/h

HP Range 0.75hp to 75hp: Single phase (upto 15hp) 230 Volts and Three phase 415 Volts

The Borana Submersible Pumps are suitable for the following applications

- Domestic and Industrial water lifting.

- Fountains.

- Farm houses and irrigation of small fields.

- Multi-Storeyed buildings.

- Water circulation systems.

- Nurseries and diaries.

- Agriculture and farming.

- Drip sprinkler irrigation.

- Water supply for domestic industrial.

- Stock watering.

- Housing complex and high rise buildings.

1) A Wide Pump Range: Borana offers energy-efficient submersible pumps ranging from 1 to 280 m 3/h. The pump range consists of many pump sizes, and each pump size is available with an optional number of stages to match any duty point.

2) High Pump Efficiency: Often pump efficiency is a neglected factor compared to the price. However, the observant user will notice that price variations are without importance to water supply economics compared to the importance of pump and motor efficiencies.

3) Material and Pumped Liquids: Borana offers a complete range of pumps and motors which, as standard, are made completely of stainless steel to AISI 304. This ensures good wear resistance and a reduced risk of corrosion when pumping ordinary cold water with a minor chloride content.

4) A pump range made of upgraded stainless steel is available for more aggressive liquids:

- BSP N: AISI 316

- BSP R: AISI 904L

For slightly polluted liquids containing for example oil, Borana offers a complete range of stainless-steel BSP NE pumps to AISI 316 with all rubber parts made of FKM.

5) Low Installation Costs: Stainless steel means low weight facilitating the handling of pumps and resulting in low equipment costs and reduced installation and service time.

6) Bearings with Sand Channels: All bearings are water-lubricated and have a squared shape enabling sand particles, if any, to leave the pump together with the pumped liquid.

7) Inlet Strainer: The inlet strainer prevents particles over a certain size from entering the pump.

8) Non-Return Valve: All pumps have a reliable non-return valve in the valve casing preventing backflow in connection with pump stoppage. Furthermore, the short closing time of the non-return valve means that the risk of destructive water hammer is reduced to a minimum. The valve casing is designed for optimum hydraulic properties to minimise the pressure loss across the valve and thus to contribute to the high efficiency of the pump.

9) Priming Screw: All Borana pumps with radial impellers are fitted with a priming screw. Consequently, dry running is prevented because the priming screw will ensure that the pump bearings are always lubricated. BSP pumps with semi-axial impellers require no priming screw. The pumps are primed automatically. It applies to all pump types, however, that neither pump nor motor will be protected against dry running if the water table is lowered to a level below the pump inlet.

10) Stop Ring: The stop ring prevents damage to the pump during transport and in case of up-thrust in connection with start-up. The stop ring, which is designed as a thrust bearing, limits axial movements of the pump shaft.

- The stationary part of the stop ring (A) is secured in the upper chamber.

- The rotating part (B) is fitted above the split cone (C).

- Water lubricated bearing.

- Long life and low weight stainless steel pumps.

- Smooth and noiseless operation.

- Low frictions carbon thrust bearings.

- Can be easily dismantled & repaired.

- 100% fabricated stainless steel submersible pumps.

- Motor designed for wide voltage fluctuation.

- Carbon bearings for long trouble fee performance.

- Water hammer protection resistance to aggressive water.

- More durability and hygiene and high operating efficiency.

- Optimal hydraulics provide high efficiency and operating costs.

- Stainless steel body for anti corrosive and rust proof long life.

- Provides very good wear resistance due to stainless steel construction.

- Fitted with tilting pad floating carbon thrust bearings for low friction and high thrust loads.

- Borana stainless steel pumps are crafted to excel in state-of-the-art production facilities and high skilled manpower.

The Borana Submersible Pumps are suitable for the following applications

- Domestic and Industrial water lifting.

- Fountains.

- Farm houses and irrigation of small fields.

- Multi-Storeyed buildings.

- Water circulation systems.

- Nurseries and diaries.

- Agriculture and farming.

- Drip sprinkler irrigation.

- Water supply for domestic industrial.

- Stock watering.

- Housing complex and high rise buildings.

1) A Wide Pump Range: Borana offers energy-efficient submersible pumps ranging from 1 to 280 m 3/h. The pump range consists of many pump sizes, and each pump size is available with an optional number of stages to match any duty point.

2) High Pump Efficiency: Often pump efficiency is a neglected factor compared to the price. However, the observant user will notice that price variations are without importance to water supply economics compared to the importance of pump and motor efficiencies.

3) Material and Pumped Liquids: Borana offers a complete range of pumps and motors which, as standard, are made completely of stainless steel to AISI 304. This ensures good wear resistance and a reduced risk of corrosion when pumping ordinary cold water with a minor chloride content.

4) A pump range made of upgraded stainless steel is available for more aggressive liquids:

- BSP N: AISI 316

- BSP R: AISI 904L

For slightly polluted liquids containing for example oil, Borana offers a complete range of stainless-steel BSP NE pumps to AISI 316 with all rubber parts made of FKM.

5) Low Installation Costs: Stainless steel means low weight facilitating the handling of pumps and resulting in low equipment costs and reduced installation and service time.

6) Bearings with Sand Channels: All bearings are water-lubricated and have a squared shape enabling sand particles, if any, to leave the pump together with the pumped liquid.

7) Inlet Strainer: The inlet strainer prevents particles over a certain size from entering the pump.

8) Non-Return Valve: All pumps have a reliable non-return valve in the valve casing preventing backflow in connection with pump stoppage. Furthermore, the short closing time of the non-return valve means that the risk of destructive water hammer is reduced to a minimum. The valve casing is designed for optimum hydraulic properties to minimise the pressure loss across the valve and thus to contribute to the high efficiency of the pump.

9) Priming Screw: All Borana pumps with radial impellers are fitted with a priming screw. Consequently, dry running is prevented because the priming screw will ensure that the pump bearings are always lubricated. BSP pumps with semi-axial impellers require no priming screw. The pumps are primed automatically. It applies to all pump types, however, that neither pump nor motor will be protected against dry running if the water table is lowered to a level below the pump inlet.

10) Stop Ring: The stop ring prevents damage to the pump during transport and in case of up-thrust in connection with start-up. The stop ring, which is designed as a thrust bearing, limits axial movements of the pump shaft.

- The stationary part of the stop ring (A) is secured in the upper chamber.

- The rotating part (B) is fitted above the split cone (C).

- Water lubricated bearing.

- Long life and low weight stainless steel pumps.

- Smooth and noiseless operation.

- Low frictions carbon thrust bearings.

- Can be easily dismantled & repaired.

- 100% fabricated stainless steel submersible pumps.

- Motor designed for wide voltage fluctuation.

- Carbon bearings for long trouble fee performance.

- Water hammer protection resistance to aggressive water.

- More durability and hygiene and high operating efficiency.

- Optimal hydraulics provide high efficiency and operating costs.

- Stainless steel body for anti corrosive and rust proof long life.

- Provides very good wear resistance due to stainless steel construction.

- Fitted with tilting pad floating carbon thrust bearings for low friction and high thrust loads.

- Borana stainless steel pumps are crafted to excel in state-of-the-art production facilities and high skilled manpower.